ABOUT CAMILLEON

Camilleon Ldt. has been a reliable player on the market of tool manufacturing in Hungary for over 20 years.

OPERATIONS

The company has been manufacturing plastic injection moulds and aluminum dies up to the weight of 35 tons for over 20 years. Our infrastructure and resources allows the production of small series unique parts as well as to manage of mould projects of 4-8 moulds.

The objective of Camilleon Ldt. is to offer an overall design and execution service for its customers.

The operations of the company are continuously expanding:

In 2018 sheet metal processing was added.

In 2020 the processing of serie production has started.

In 2022 zinc casting was added.

CONTINOUS DEVELOPMENT

Camilleon Ldt. was one of the first in the field of automation: the company has been using a robot cell for the production of graphite electrodes since 2009. In order to reach the optimal efficiency, we use the EROWA positioning system throughout the whole production process.

ABOUT CAMILLEON

Camilleon Ldt. has been a reliable player on the market of tool manufacturing in Hungary for over 20 years.

OPERATIONS

The company has been manufacturing plastic injection moulds and aluminum dies up to the weight of 35 tons for over 20 years. Our infrastructure and resources allows the production of small series unique parts as well as to manage of mould projects of 4-8 moulds.

The objective of Camilleon Ldt. is to offer an overall design and execution service for its customers.

The operations of the company are continuously expanding:

– In 2018 sheet metal processing was added.

– In 2020 the processing of serie production has started.

– In 2022 zinc casting was added.

CONTINOUS DEVELOPMENT

Camilleon Ldt. was one of the first in the field of automation: the company has been using a robot cell for the production of graphite electrodes since 2009. In order to reach the optimal efficiency, we use the EROWA positioning system throughout the whole production process.

THE KEY TO THE SUCCESS OF THE ORGANIZATION IS CUSTOMER SATISFACTION. OUR WAY OF ACHIEVING SATISFACTION:

Diversification of the scope of activities and industry segments of the customers

Enhancing the added value of products and expanding the variety of operations according to customer needs

Inclusion of the customer in product development

Innovation of complexity: implementation of projects from tool design to serial production

Diversification of the scope of activities and industry segments of the customers

Enhancing the added value of products and expanding the variety of operations according to customer needs

Inclusion of the customer in product development

Innovation of complexity: implementation of projects from tool design to serial production

Tool manufacturing

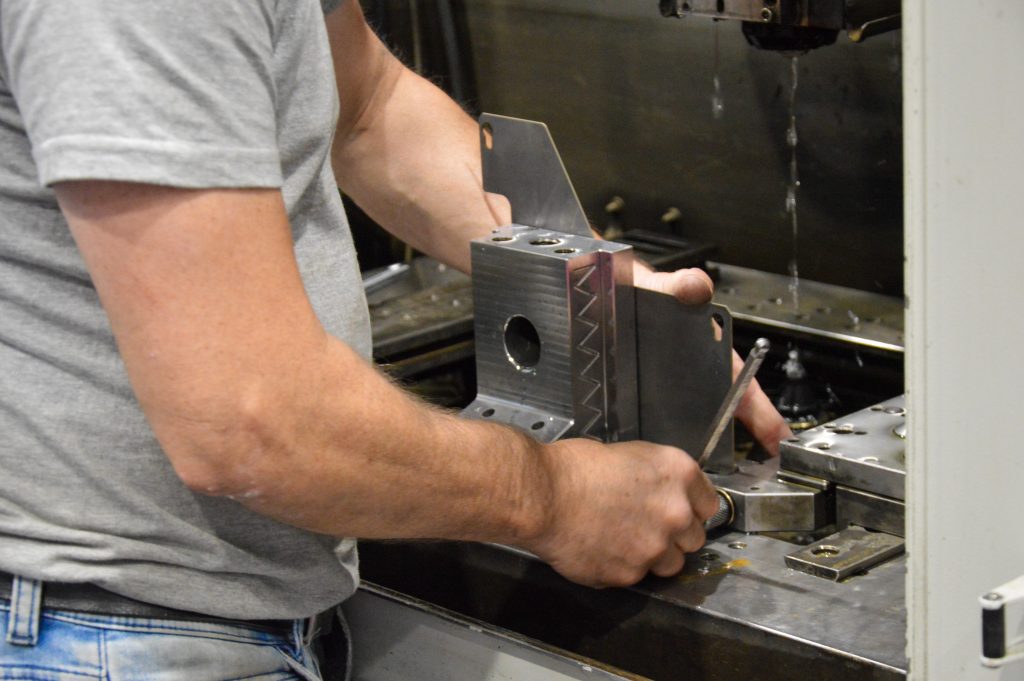

The founders of Camilleon Ldt. themselves have had a professional history in the field of CAM programming and it has continued to be of high importance throughout the development of the company. During CAM programming the softwares SolidEdge, Unigraphics and Powermill are used in the tool design processes. With the assistance of our partner casting simulations with the NovaCast NovaFlow&Solid software are also made possible. The manufacturing of the tools is done by a continuously evolving, state of the art machinery set. The company owns sink and wire erosion machines, 3D and continuous 5D CNC machining centers, that can be used for complex parts that are up to 2000×3000 mms in size. We work with highly trained and experienced professionals, as well as a 40 ton crane and its complementary fitting press to assemble our tools.

CNC cutting

For the processing of small, medium and large series we are equipped with:

– 3 pcs 4 axis machining centers with palett changer

– 1 pc CNC lathe machine

Camilleon Ldt. has experience in machining part for the automotive, electronics, gas and pneumatic industries.

The tools can be made out of:

– steel

– stainless steel, aluminium (casted or blank raw material)

– zinc (casted or blank raw material)

– plastic

for series from a couple hundred to up to hundreds of thousands of pieces.

The concept of processing and the specific devices are designed by professionals with decades of experience, and they are manufactured by the tool manufacturing department. The tools are measured in measuring rooms by two CNC coordinate measuring machines, one profile projector and one contour measuring machine.

Casting

Camilleon Ldt. has been producing parts out of zinc-based alloys with hot chamber casting machines since 2022.

With this technology it is possible to produce relatively small products with precise and high size and aesthetic quality as well as a long tool lifespan.

The company is equipped with three casting machines:

– Frech hot chamber casting machine, closing force 40 t

– LK hot chamber casting machine with manipulator, closing force 88 t

– LK hot chamber casting machine with FANUC robot, closing force 133 t

The capacities enable the unique design of the entire process of the product, moulds, and the manufacturing technology. The casting produced can weigh from 10 grams up to 1000 grams.

To serve complex customer needs we are currently adding tumbling, blasting and powder painting capacities.

Pressing

In 2020, an H framed excentric press with 160t closing force equipped with an automatic foil remover, decoiler and feeder has been set up for operation. We press medical technology tools out of anodized aluminum, which must meet high aesthetic standards. To assure stable and reliable quality, we connected an artificial intelligence controlled automatic optical sorting system to the device, enabling us to serve our customers practically with no mistakes. In addition to using aluminum, we are also enable to use steel sheet with a width of 2 mms when produced out of the roll, and a width set by the clamping force in case of manual feed operation.